Customized CNC Precision Machining Gray/Grey/Ductile Cast Iron Manufacturer for Railway/Train Casting Parts

Product Details

| Item | Train/Railway Parts |

| Surface Roughness | Ra0.05∼Ra50, Depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting Tolerance | CT5-CT8 |

| Coating | Electrophoresis Coating |

| Machining | Lathing, Milling, Turning, Boring, Drillig, Tapping, Grinding, etc |

| Machining Tolerance | 0.01mm |

| Design Software/ Formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works, CAXA, Rhino, CATIA, SIMIO, ALIAS, ARENA, Unigraphics |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

| Dimension Inspection | Coordinate Measuring Machine (CMM), Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle And R Gauge, Customized Gauge, etc. |

| Package | Bubble Plastic Bag, Polybag, Pallet, Wooden Case |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| OEM/ODM Service | Available |

Product Description

| General Products Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. |

| Main blank Process for Casting | Sand Casting , Resin Sand Casting, Green Sand Casting, Shell Molding, Automatic Molding, Lost Wax Casting, Lost Foam Molding Casting |

| Blanks Tolerance -Casting Tolerance | CT9-10 for Machine Molding Process, CT8-9 for Shell Molding and Lost Foam Molding Casting Process CT10-11 for Manual Molding Sand casting Process |

| Applicable Material | See Table Below (Ductile Iron Casting, Grey Iron Casting) OR According to customer requirement |

| Casting Blank Size/Dimensions | 2 mm-2000mm/0.08inch-79inch for casting iron, according to customer requirement |

| Casting Blank Weight | Range from 0.01kg-1000kg for casting iron |

| Applicable Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. |

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

| Machined Surface Quality | Ra 0.8-Ra3.2, according to customer requirement |

| Applicable Heat Treatment | Normalization , annealing, quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching |

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting. |

| MOQ | For iron casting : 100pcs For Machining : 50pcs |

| Lead Time | 45 days from the receipt date of deposit for iron casting |

Advantages Of The Stainless Steel

1. The inner wall is smooth to avoid the occurrence of impurity condensation.

2. Stainless steel can work safely at - 270 ~ 400 ºC for a long time and has stable performance.

3. Its tensile strength is more than 530n / m³, 2-10 times higher than that of ordinary materials.

4. Stainless steel has a thin and dense oxide film, which prevents the further oxidation reaction.

5. Excellent wear resistance.

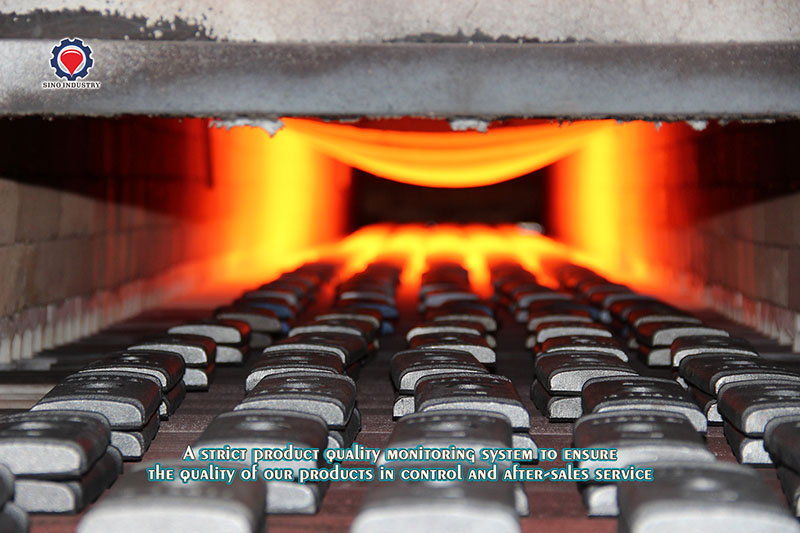

Quality Control

1. Checking the details before the production line operated

2. Have full inspection and routing inspection during mass production---In process quality control(IPQC)

3. Checking the goods after they are finished---- Final quality control(FQC)

4. Checking the goods after they are finished-----Outgoing quality control(OQC)

Sand casting process

Pattern Design -> Pattern Manufacture -> Pattern Test -> Qualified Sample -> Mass Production -> Sand Shakeout -> Polishing -> Sand Blasting -> Surface Treatment (panting) -> CNC machining -> Inspection -> Clearning & Anti-rust -> Packing & Shipping QC System: raw material inspection, FAI, IPQC, random inspection, final full inspection before shipping. Standard: ANSI , ASME, DIN, BS, JIS, ASTM, GB etc.

OEM/ODM/Customization Casting Service

Products showed here are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available.

Please send us your detailed drawings/samples/requirements to enable us to offer you a formal quotation.

Our policy is that none of these products will be sold to 3rd parties without written consent of the customers to whom the tooling, design and specifications belong.

Advantages of Casting Parts

1. Wide suitability.The metal casting process almost free from the restrictions of the size, thickness and shape of castings, casting wall thickness can be up to 0.3-1000 mm, the length varies from a few millimeters to ten meters, and the quality can be from a few grams to more than 300t.

2. With a higher specific pressure, the dimensional accuracy and surface finish of the castings are higher.

3. The whole line has a high degree of automation. The operator only needs to control the button base to check the production line. The labor intensity is low, there is no shock during the production process, and the noise is low.

4. High production efficiency, generally up to 450 type/hour or more, simple equipment matching and few failures.

5. Good economy, no sand box, few auxiliary machines, and low daily maintenance.

Technical Support

We are professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D softwares. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Sino Industry and Trade Co., Ltd.

We specialize in custom metal parts for Mechanical Parts, industry machine parts, Agricultural machinery parts, building materials, auto cars accessaries, medical facilitiy, solar energy system, exhibition, assembly line etc. Providing one-stop service (extrusion+ heat treatment + machining + surface treatment), to save time and costs and reduce risk of quality control for you. With keeping manufacturing process design, quality planning, key manufacturing processes and final quality control in house, we are mastering key competence to supply quality casting iron parts to our customers for both China and Export Market. During the early involvement of the customer's design process we are able to provide professional input to our customers in terms of process feasibility, cost reduction and function approach. You are welcome to contact us for technical enquiry and business cooperation.

For train/railway parts, major products are as follows:

train parts, train components, train accessory, locomotive parts, locomotive components, locomotive accessory, railway parts, railway components, railway accessory, railroad parts, railroad components, railroad accessory, high-speed rail parts, high-speed rail components, high-speed rail accessory, machinery parts, machinery components, machinery accessory, railway wheels, wheelset, forging parts, forging components, forging accessory, machining parts, machining components, machining accessory, cnc machining parts, cnc machining components, cnc machining accessory, cnc parts, cnc components, cnc accessory, machine parts, machine components, machine accessory, precision casting, precision machining, precision cnc parts, train spare parts, hardware parts, stainless steel, vehicle parts, equipment parts, equipment components, equipment accessory, device parts, device components, device accessory, facility parts, facility components, facility accessory, railway track, train track, joint bar, fastener system, rail fastening system, angle bar, railway tie plate, railing base plate, railway fastener system, railway fastener, railway shoulders, forging rail anchor, rail fastener, railway fastening, railway anchor, subway parts, subway components, subway accessory, railway precise machining, railway wheel hub, railroad spring, railway coupler, victaulic, transportation parts, railway wagon, railway side frame, railway axle, train axle, railway bolster, wagon bogie, railway wheel, bogie car, railway bogie, locomotive wheelsets, locomotive spring, railway wagon parts, railway wagon components, railway wagon accessory, etc.

Our Vision

Keeping Continuous improvement on technology and engineering innovation, becoming a strong, stable and high competence top metal working supplier in one of our business sections with focus on Vehicle and Manufacturing Industries and continuously satisfy our customers.

FAQ

Q1: How long is your delivery time?

A:Delivery time depends on the total quantity of order. Normally, sample can be delivered within 15 days.

Q2: Do you provide samples? Is it free or extra?

A:Yes, we could offer sample for free, and we can pay for the model as well, but the clients has to pay for the shipping cost.

Q3: What is the MOQ of your products?

A:It depends on the category of the order.

Q4: Where is your factory?

A:Our factory is located in Rizhao City, Shandong province, P.R. China, its only one and a half hours’ drive from our factory to the nearest shipping port.

Q5: Do you test all your goods before delivery?

A: Yes, advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers. Each batch of products from raw materials to finished products will be tested in the laboratory to ensure that the quality is up to the standards, and each batch of finished products will be carried out spectral inspection. For specific products tensile test will be conducted to ensure the tensile strength of products up to the standards. We will provide our customers with test reports.

Q6: How do you make our business long-term and good relationship?

As a leading manufacturer in the casting/forging/machining industry, we are commited to offer high quality products with competitive prices and excellent service worldwide. We stick to the quality management philosophy that "Starting from the customer needs and ending with their satisfaction". We Focus on customer demands and exceeding their expectations. And we have been honing our competitive edge to remain ahead of others. Customers’ satisfaction is our everlasting pursuit. We look forward to building a long, lasting and mutual beneficial business relationship with each of buyers!